Published

- Sustainability

- Guarantees

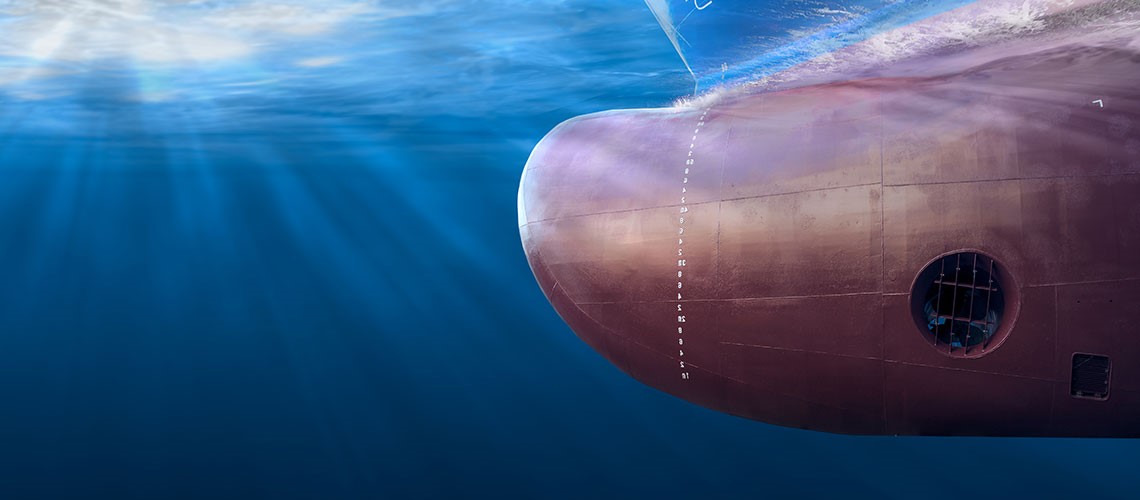

No more free cruises for invasive species

The mandatory ballast water treatment systems required under new maritime regulation is a major investment to smaller and midsize shipping companies. Supplier credit guarantees from EKN help spread the cost and boost exports of Alfa Laval’s market-leading solutions.

The rapid increase in world trade has brought growth and prosperity to countless people across the globe. Commercial maritime vessels, however, carry more than coveted goods: Their ballast water may transport sea-living organisms such as bacteria, microbes, small invertebrates, eggs, cysts and larvae to ecosystems where they don’t belong and lack natural enemies.

The introduction and spread of alien invasive species is a serious global threat to marine and freshwater ecosystems. New species may completely alter the local communities, drive species to extinction as well as cause economic damage. Described as one of the four greatest threats to the world’s oceans, bio-invasions continue to increase at an alarming rate and new areas are being invaded all the time.

IMO requirement by 2024

Necessary for a ship’s stability and manoeuvrability, ballast water helps balance the payload, which varies depending on whether cargo has been loaded or offloaded at port. To combat the problem of invasive species, the International Maritime Organization (IMO) has required that all vessels must be fitted with a certified ballast water treatment system (BWTS) by 2024. Those that fail will be denied access to commercial ports.

How is ballast water treated? Merely using mechanical filters won’t stop microscopic organisms from entering the ballast tank when water is pumped on board – additional disinfection is needed, usually through exposure to ultraviolet (UV) rays or chlorination. Swedish Alfa Laval has opted for the former, a common method for purifying drinking water that has no negative impact on the environment.

Among the first vendors to market a certified BWTS solution, Alfa Laval has seen demand skyrocketing since stricter regulations were first announced in 2016.

“Being an early mover and among the first to offer a certified solution, we clearly anticipated the need to retrofit existing vessels,” says Linus Brohlin at Alfa Laval Business Development.

Supplier credit guarantees from EKN

The cost of retrofitting a ship with a BWTS runs between 90,000 and 500,000 euros, depending on vessel size and capacity requirements.

“This is a major investment to smaller and midsize shipping companies, whose revenues are fluctuating in tandem with the general economic development and rapidly shifting freight rates. To be able to offer our customers an attractive solution that included financing, we turned to EKN.”

By offering supplier credit guarantees from EKN for a duration of between 3–5 years, Alfa Laval gives shippers a chance of spreading the financial burden of a BWTS retrofit over a longer period.

“It’s not just good news for the shippers, but for their banks as well, since EKN’s guarantee lowers the customer credit risk,” adds Brohlin.

From a sustainability perspective, the partnership makes a lot of sense, says Michael Regmert, senior underwriter at EKN:

“Alfa Laval’s solution protects the maritime environment, so we’re happy to help out.”

Currently in its third generation, PureBallast 3.2 works in all types of water – fresh, brackish and oceans – and even in murky waters (such as busy ports often offer) with UV transmittance as low as 42 percent. Over 1,200 systems have been sold to date, including more than 300 installed as retrofits. The components are manufactured in Aalborg, Denmark, but R&D, management and marketing functions are based in Tumba outside Stockholm.

Facts

What is ballast water?

Ballast water is essential for the safe operation of ships. It provides stability and manoeuvrability during a voyage and during loading and unloading operations. Ships are designed and built to move through water carrying cargo, such as oil, grains, containers, machinery and people. If the ship is traveling without cargo, or has discharged some cargo in one port and is on route to its next port of call, ballast water may be loaded on board to achieve the required safe operating conditions. Among others this includes keeping the ship deep enough in the water to ensure efficient propeller and rudder operation.

Water has a good weight-to-volume ratio and is carried in separate tanks used just for ballast, or in empty cargo tanks. When a vessel is departing a port, water and any sediment that may be stirred up, is loaded into the ballast tanks and unloaded again when it takes on cargo at the next port. However, the process of loading and unloading untreated ballast water poses a major threat to the environment and public health as ballast water impacts the transfer of organisms between ecosystems, from one part of the world to another.

The problem of invasive species in ships’ ballast water is largely due to the expanded trade and traffic volume over the last few decades and, since the volumes of seaborne trade continue to increase, the problem may not yet have reached its peak yet. The effects in many areas of the world have been devastating.

Source: Government of Canada